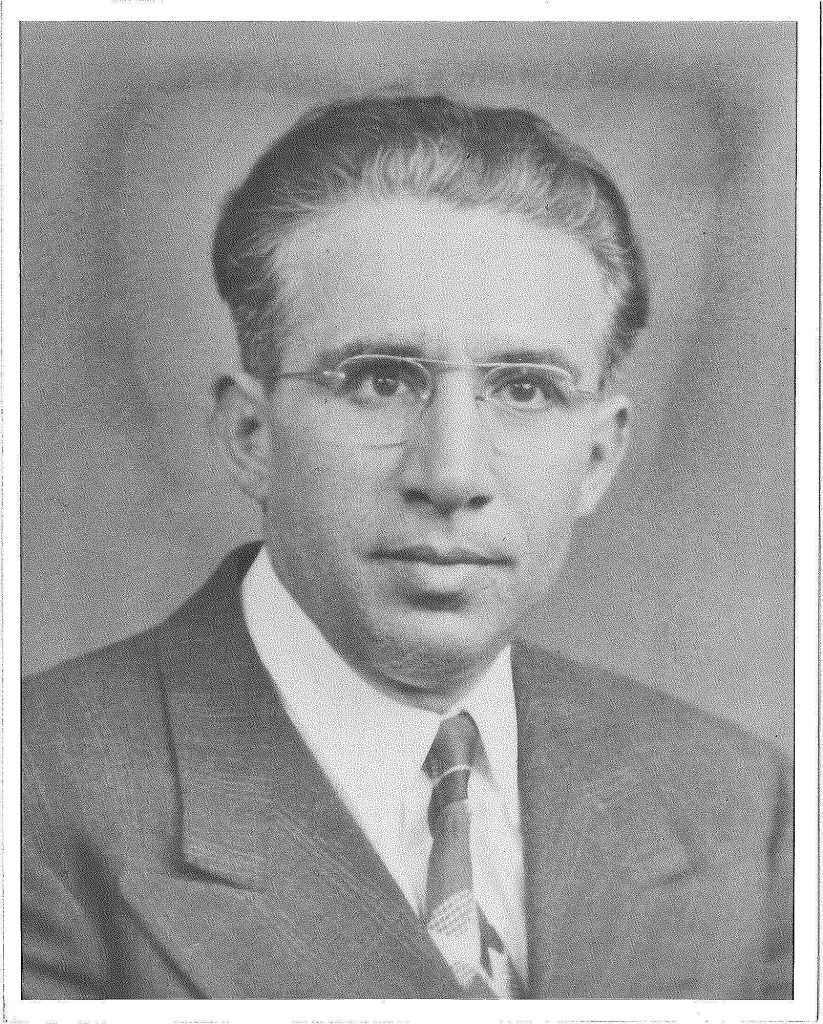

The Scuderi family, owners of VBC, have been continuously manufacturing closures since 1924. Van Blarcom Closures, Inc. was incorporated in Brooklyn, NY February 3, 1947.

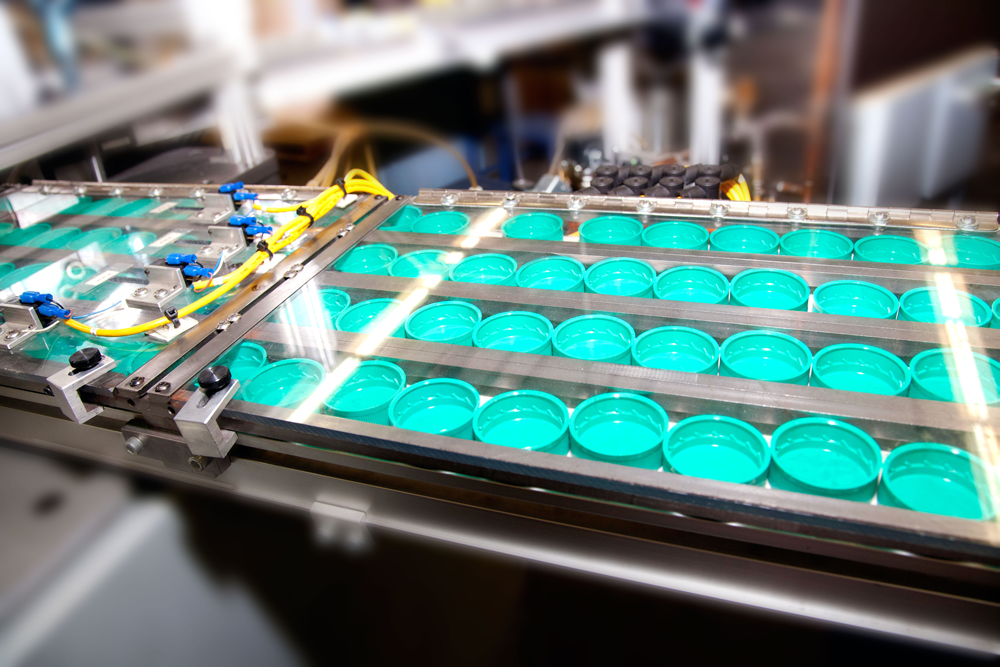

Prior to 1972, VBC manufactured metal threaded closures and fitments for the can industry as well as cork lined crown closures as used by the beverage industry. Subsequent to the passage in 1972 of the Poison Prevention Packaging Act (P.P.P.A.), hazardous products which were primarily packaged in metal cans now required child resistant packaging. VBC quickly responded with their development of Saf-Cap™, a two-piece metal child resistant closure. Modifications soon produced a plastic overcap version. This introduction into plastics paved the way for VBC’s entry into the pharmaceutical and household chemical industries with an all plastic millimeter sized two piece push-down-and-turn child- resistant closure, Saf-Cap™ I.

Saf-Cap™ I gained popularity quickly. Sales grew at an outstanding rate in an industry that was lready flooded with designs from competing manufacturers. Today, sales of Saf-Cap™ closures account for over 90% of VBC’s total business.

The design benefits of Saf-Cap™ were proven in an independent study performed for the U.S. Consumer Products Safety Commission in 1988. In this study the Saf-Cap™ closure was demonstrated as being the most consumer friendly. The results of which were used as a building block in the development and eventual adoption of the present regulations governing child-resistant packaging requirements.

Further developments included Saf-Cap™ II, Saf-Cap™ III and Saf-Cap™ III-A child resistant closures and the Saf-Cap™ I CR dropper closure. Our development group continually pursues new and improved designs of closures as well as the design and manufacture of specialty dispensing and medical devices.